Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

With our diverse payload options, inspections of pipeline right of ways (ROWs) can be conducted in a safer and more cost-effective manner without compromising on the quality of critical information gathered during the inspection.

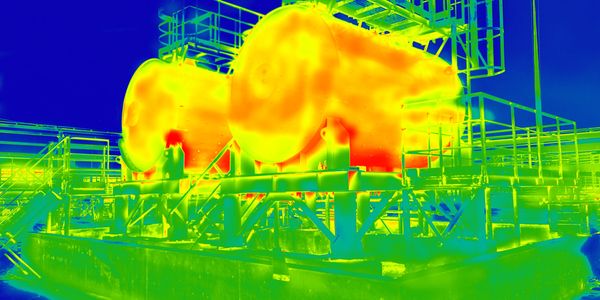

Our UAVs can be outfitted with a combination of high resolution video and cutting edge thermal payloads, ensuring no detail is missed during an inspection. If required, our UAVs can also be outfitted with gas detection (laser) payloads to inspect riser sites or other areas of interest for potential leaks. When combined with LiDAR or Bathymetric payloads, slope monitoring and river crossings can also be inspected, eliminating the need to dispatch personnel or implement costly stationary technology to provide historical data on these high-potential-risk locations.

Real-time, in video geotagging provides the user with accurate location information on any points of interest observed during an inspection.

Occasionally an inspection is required on equipment that may be located at heights, in an area with limited or remote means of access, or in a location hazardous to inspection personnel.

With our available payload options, these inspections that would otherwise represent a potential risk to inspection personnel, a significant logistical challenge, or a high cost can be completed safely, simply, and cost-effectively.

With options ranging from high resolution video and photo systems, industry leading thermal imagery, precision gas detection technology (OGI or Laser), and more, no equipment inspection task is beyond reach.

When equipped with our high resolution video and photo payloads, our UAV solutions provide clients seeking a means of inspecting large amounts of equipment quickly and effectively with an option that eliminates the need to have personnel on location, reducing the risk and potential expense associated with these inspections.

When combined with our thermal payload options, details such as insulator failure or abnormal equipment temperatures can be observed, preventing potentially catastrophic equipment failures.

With our high resolution video and photo offerings, completing a roofline or eavestrough inspection on your home has never been easier. Quickly identify damaged or missing roof components such as shingles or vents, and easily spot plugged or damaged eavestrough along the way, all without the need for ladders or costly bucket-lift trucks and technicians.

Our thermal solutions aren't limited to industrial applications; they can also be used to complete detailed inspections of residential housing, highlighting any potential gaps in your insulation which can lead to costly impacts to your heating bill.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.